VRM - THE LATEST TECHNOLOGY

VRM - THE LATEST TECHNOLOGY

Vertical Roller Mill (VRM) is the most advanced technology in cement production procedure. Bashundhara Cement has adopted VRM from LOESCHE, Germany in both the factories to ensure the best quality. With higher fineness achieved with VRM, it creates stronger and better quality concrete and thus, proves its superiority over other cement brand.

- High Finenss

- Better Particle Size Distribution (PSD)

- Faster Setting Time

- Less Energy Consumption

VRM - THE LATEST TECHNOLOGY

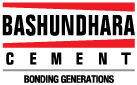

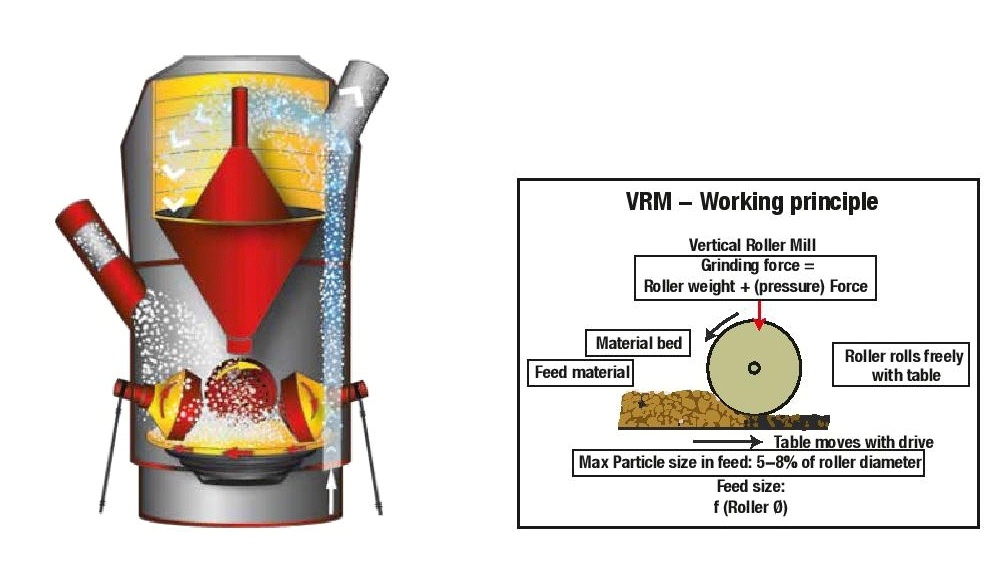

The VRM is a vertically placed large sized machine which is equipped with some rollers used for grinding raw material. It also consists of one table which is rotated by electrical motor & raw materials are feeded on the table. Due to centrifugal force on the table, raw material goes below the rollers (a gap between roller & table has to be maintain) automatically & start getting grinded. The rollers are driven by the friction between table & raw materials. The grinding process is done by exposing a bed of material to a pressure sufficiently high created by rollers which causes fracture on the individual particles in the bed. Due to such grinding, fine particles pass through the separator as the final product to the silo due to huge negative pressure in the mill & course particles falling down (separated by highly efficient separator)on the table for further grinding.

Suitable grinding bed is easily obtained in vertical roller mill with high efficiency separator which ensures high fineness of product.

Superiority

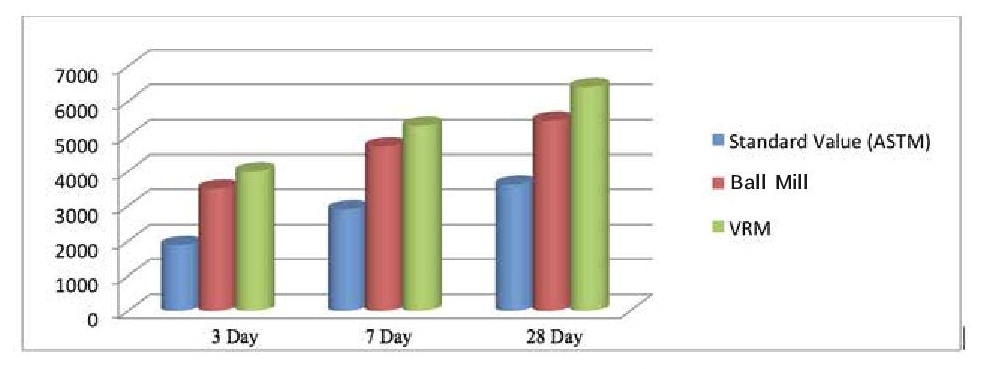

A. The grinding process of Ball mill & Vertical Roller Mill differs fundamentally. The sufficiently high enough to cause fracture of individual particles in the bed & most of the particles on the bed are considerable, smaller than the bed thickness. On the other hand, in a Ball mill, the comminution takes place by impact & attrition.

B. A suitable grinding bed is easily obtained in vertical roller mill with high efficiency separator which ensures high fineness of product. However, in the Ball mill, it is more difficult to get suitable grinding bed.

C. By automatic grinding process in the grinding bed, Uniform percentage of materials can be maintained which leads to perfect product composition

D. Particle size distribution (PSD) of the finished product obtained from VRM is much better than Ball mill product. High fineness of material ensures more dense concrete with less possibility of chemical attack.

E. In VRM, there is a system to remove unnecessary wastes and by products, ensuring unique quality cement.

F. VRM produces less than 85 dB sound while in production. This modern technology does not release fine particles to the air. So there is no possibility of environment pollution.